Transform your industrial laundry facility into a high-efficiency powerhouse by starting with a comprehensive workflow analysis. Map out distinct zones for sorting, washing, drying, and folding to create a natural progression that minimizes worker movement and maximizes productivity. Strategic placement of commercial washers along moisture-resistant walls, with clear 36-inch maintenance access paths, enables seamless operation while meeting safety compliance standards.

Design your space around peak capacity requirements, allocating 120 square feet per industrial washer-dryer set and incorporating dedicated staging areas that prevent bottlenecks during high-volume periods. Install commercial-grade ventilation systems capable of 15 air changes per hour, paired with moisture-resistant flooring pitched at a 1/4-inch per foot slope toward central drains.

Factor in ergonomic considerations by positioning folding stations at optimal working heights (36 inches), installing adequate LED lighting (minimum 500 lux), and incorporating sound-dampening materials to create a more comfortable working environment. This thoughtful approach to industrial laundry design not only boosts operational efficiency but also ensures worker safety and equipment longevity while meeting all relevant health and safety regulations.

Essential Layout Principles for Maximum Efficiency

The Flow-Through Design Concept

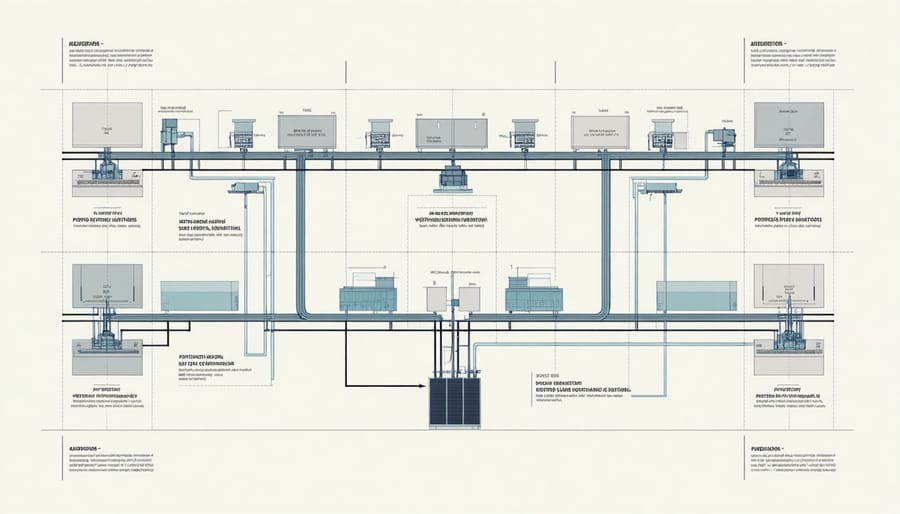

The key to a successful industrial laundry operation lies in an efficient layout design that follows a logical flow-through pattern. Think of it as a production line where laundry moves seamlessly from one stage to the next, minimizing bottlenecks and maximizing productivity.

Start by establishing a clear sorting zone at the entrance, where soiled items can be categorized by fabric type, color, and washing requirements. This area should have ample space for sorting bins and carts, with easy access to the washing zone. Position your commercial washers in a linear arrangement, allowing for smooth loading and unloading operations.

The drying zone should naturally follow the washing area, with enough space between machines for laundry carts to maneuver easily. Consider installing overhead rails or implementing a cart system to transport items efficiently between zones. The folding area comes next, requiring well-lit, spacious countertops and tables for careful inspection and precise folding.

Finally, create a designated storage and dispatch zone where clean, folded items can be organized and prepared for delivery or storage. This area should be furthest from the soiled sorting zone to prevent cross-contamination. Remember to incorporate wide aisles throughout the space to accommodate peak-time traffic and ensure smooth movement of both staff and laundry carts.

This linear flow reduces walking distances, increases productivity, and maintains proper hygiene standards – essential elements for any successful industrial laundry operation.

Space Requirements and Traffic Patterns

When designing an industrial laundry room, proper space planning and traffic flow are crucial for maximizing efficiency. Start by implementing proven workspace optimization techniques that allow for smooth movement between different work zones.

Allow at least 4 feet of clearance between machines for maintenance access and operator movement. Create dedicated lanes for dirty and clean laundry to prevent cross-contamination, with a minimum width of 5 feet for cart traffic. Position sorting stations near the entrance and folding areas close to the exit to establish a logical workflow.

Consider installing overhead rails or implementing a conveyor system to minimize manual transportation of heavy loads. Place frequently used equipment within easy reach, and ensure adequate space around folding tables – typically 3 feet on all sides for comfortable movement.

Remember to account for storage needs by incorporating shelving units and supply closets along the walls, keeping the central floor space clear for traffic. Plan for future growth by leaving some flexible space that can accommodate additional equipment if needed.

For optimal safety and efficiency, mark traffic lanes clearly on the floor and install proper lighting throughout the space. This helps prevent congestion and ensures smooth operations during peak times.

Equipment Selection and Placement

Commercial Machine Specifications

When selecting commercial laundry machines, focus on durability and efficiency to ensure your investment pays off in the long run. Look for washers with high G-force extraction rates (300G or higher) as these remove more water during the spin cycle, reducing drying time and energy costs. Opt for machines with programmable controls that allow customization of wash cycles, water temperatures, and chemical dosing to handle various fabric types.

For industrial washers, key specifications include:

– Capacity ranging from 20 to 125 pounds

– Heavy-duty steel construction

– Double-sealed bearings for longevity

– Advanced shock absorption systems

– Multiple water inlet valves

– Professional-grade door seals

– Built-in chemical injection ports

Industrial dryers should feature:

– Reversing cylinders to prevent tangling

– Multiple temperature settings

– Moisture sensing capabilities

– Large door openings for easy loading

– Heavy-duty drum support rollers

– Industrial-grade heating elements

– Advanced lint filtration systems

Energy efficiency ratings are crucial – look for ENERGY STAR certified machines that can reduce utility costs by up to 30%. Consider machines with automatic chemical dispensing systems to ensure consistent results and prevent waste. Soft-mount machines are ideal for upper floors as they require minimal foundation work, while hard-mount units need concrete bases but often cost less initially.

Remember to verify warranty terms and availability of local service technicians before making your final selection. The best machines offer diagnostic systems that help identify issues quickly, minimizing downtime and maintenance costs.

Strategic Equipment Positioning

The heart of an efficient industrial laundry operation lies in smart equipment placement. Start by positioning your washers and dryers along the same wall whenever possible, creating a clear workflow from dirty to clean. Leave at least 3 feet of clearance around each machine to allow for maintenance access and proper ventilation.

Consider creating designated zones within your space: a receiving area for soiled items, a sorting station, washing zone, drying area, and folding/finishing section. This linear arrangement minimizes cross-contamination and keeps your workflow smooth and efficient.

Place your sorting tables near the entrance where soiled items arrive, but maintain a clear separation from clean processing areas. Position folding tables and finishing equipment in well-lit areas, ideally near windows if available, to help staff spot stains or quality issues.

When installing washers, ensure they’re close to drainage points and hot water supplies to minimize plumbing costs and maximize efficiency. Dryers should be positioned near external walls to keep vent runs as short as possible, improving performance and reducing fire risks.

Don’t forget about your support equipment! Install supply shelving and chemical storage units within easy reach of the washing area, but separate from clean zones. If using laundry carts, plan for clear pathways at least 4 feet wide to allow easy movement between stations.

Remember to keep fire exits clear and maintain adequate space around electrical panels. A well-thought-out equipment layout not only boosts productivity but also ensures safety and compliance with workplace regulations.

Storage Solutions That Work

Supply Organization Systems

Effective organization is crucial for maintaining a smooth-running industrial laundry operation. Implementing smart storage solutions for laundry facilities can dramatically improve workflow and efficiency.

Start by creating designated zones for different supplies. Install heavy-duty shelving units for detergents and cleaning chemicals, ensuring they’re properly labeled and easily accessible. Consider using clear containers to quickly identify low inventory levels. For safety, store chemicals above floor level but below eye level, and always maintain proper ventilation in storage areas.

For linens, implement a first-in-first-out (FIFO) system using mobile carts or shelving units. Color-code different types of linens or use clear labeling systems to prevent mix-ups. Install overhead racks for hanging items that require air-drying or special handling.

Utilize wall space effectively by mounting supply dispensers and organizing tools on pegboards. Include a designated area for sorting and folding with built-in cabinets underneath for additional storage. Consider installing a supply tracking system to maintain optimal inventory levels and prevent shortages.

Keep frequently used items at arm’s reach and less commonly used supplies in secondary storage areas. Remember to include a secure location for valuable items and a separate space for maintaining cleaning equipment and tools.

Mobile Storage Solutions

In an industrial laundry setting, flexibility is key, and mobile storage solutions offer the perfect balance of functionality and adaptability. Rolling carts, mobile shelving units, and wheeled storage containers allow you to easily reconfigure your space as needs change while organizing supplies effectively.

Consider investing in heavy-duty laundry carts with multiple tiers for sorting and transporting linens. These workhorses can handle substantial loads while smoothly gliding between washing and folding stations. Look for options with rust-resistant materials and locking wheels for safety.

Mobile supply caddies are perfect for keeping cleaning products, detergents, and tools within arm’s reach wherever they’re needed. Choose caddies with divided compartments and spill-proof edges to prevent accidents and maintain a tidy workspace.

For temporary storage needs, collapsible bins and stackable containers on wheels provide instant flexibility. These can be easily tucked away when not in use, maximizing your available floor space. Wire mesh designs are particularly useful as they allow for ventilation and visible inventory management.

Remember to select mobile storage solutions with ergonomic handles and smooth-rolling wheels to prevent strain on your staff. The ideal height should minimize bending and reaching, while sturdy construction ensures longevity in a high-traffic environment.

Safety and Compliance Features

Required Safety Equipment

Safety should always be your top priority in an industrial laundry setting. Start with proper ventilation systems to manage heat and moisture, including carbon monoxide detectors near gas-powered equipment. Install emergency shut-off switches at easily accessible locations throughout the space, and clearly mark them with visible signage.

Fire safety equipment is non-negotiable. Mount ABC-rated fire extinguishers every 75 feet, and install a sprinkler system that meets local building codes. Emergency eyewash stations and first-aid kits should be readily available, especially near chemical storage areas.

Don’t forget about slip-prevention measures. Use non-slip flooring materials and place anti-fatigue mats in high-traffic areas. Install proper drainage systems to prevent water accumulation, and ensure adequate lighting throughout the space to prevent accidents.

Emergency exits need to be clearly marked with illuminated signs and kept obstacle-free at all times. Consider installing emergency lighting that automatically activates during power outages. For chemical safety, maintain an updated Safety Data Sheets (SDS) binder and proper chemical storage cabinets with ventilation.

Personal protective equipment (PPE) stations should include heat-resistant gloves, safety goggles, and protective aprons. Finally, post clear emergency procedures and contact numbers in visible locations, and ensure all safety equipment undergoes regular maintenance and inspection according to manufacturer guidelines.

Compliance Checklist

When designing your industrial laundry room, staying compliant with regulations isn’t just about following rules – it’s about creating a safe, efficient space for everyone. Here’s your friendly guide to the essential compliance requirements:

First, ensure proper ventilation systems are in place. Your space needs to maintain 5-15 air changes per hour, with external venting for dryers to prevent moisture buildup and maintain air quality.

For electrical safety, install GFCI outlets throughout the laundry area and keep all electrical connections at least 6 feet away from water sources. Make sure your wiring can handle the power load of multiple industrial machines running simultaneously.

Flooring is crucial – use non-slip, water-resistant materials and ensure proper drainage with a slope of at least 1/8 inch per foot toward floor drains. Install emergency floor drains to prevent flooding.

For fire safety, mount clearly visible fire extinguishers every 75 feet, install smoke detectors, and maintain clear pathways to emergency exits. Your doors should swing outward and be at least 36 inches wide.

Don’t forget ADA compliance: maintain 36-inch-wide aisles, ensure front-loading machines are accessible, and keep controls within reach range (15-48 inches from the floor).

Remember to post clear signage for emergency procedures, chemical handling protocols, and machine operation instructions. Keep material safety data sheets (MSDS) readily available for all cleaning products used in the facility.

Finally, schedule regular inspections of all equipment and maintain detailed maintenance logs to stay ahead of potential compliance issues.

Ventilation and Utility Considerations

Ventilation Requirements

Proper ventilation is crucial in an industrial laundry room to maintain a safe, comfortable working environment and protect your equipment. A well-designed ventilation system helps control humidity, remove excess heat, and eliminate potentially harmful fumes from cleaning products.

Start by installing high-capacity exhaust fans that can handle the significant moisture output from multiple commercial washers and dryers. Position these fans strategically near the dryers to efficiently remove hot, humid air. For every 100 square feet of laundry space, aim to have ventilation that provides at least 10 air changes per hour.

Humidity control is equally important. Install dehumidifiers rated for commercial use to maintain optimal humidity levels between 50-60%. This helps prevent mold growth, protects your equipment from rust, and creates more comfortable working conditions.

Consider implementing a make-up air system to replace the air being exhausted. Without proper make-up air, your facility could develop negative air pressure, making doors hard to open and affecting equipment performance. Make sure all dryer vents are properly sealed and directed outside, using smooth-walled metal ducts with minimal bends for maximum efficiency.

For additional climate control, install ceiling fans to improve air circulation and help maintain consistent temperatures throughout the space. Remember to regularly clean and maintain all ventilation components to ensure they continue operating at peak efficiency.

Utility Setup Guidelines

Setting up utilities correctly is crucial for your industrial laundry room’s efficiency and safety. Start with electrical requirements: you’ll need 220V outlets for commercial washers and dryers, plus standard 110V outlets for smaller equipment. Plan for dedicated circuits to prevent overloading, and consider installing surge protectors to safeguard your expensive machines.

For water connections, ensure both hot and cold water lines are properly sized to handle multiple machines running simultaneously. Install commercial-grade shut-off valves for each washer and consider a water softening system to protect your equipment from mineral buildup. Floor drains should be strategically placed and connected to appropriately sized drain lines that meet local codes.

Gas-powered dryers require careful planning for ventilation and safety. Install commercial-grade gas lines with individual shut-off valves for each unit. Proper ventilation is non-negotiable – each dryer needs its own dedicated vent line made of rigid metal ducting, leading directly outside. This approach aligns with sustainable facility design principles while ensuring safety.

Don’t forget to include adequate ventilation for the entire room, with exhaust fans to manage humidity levels. Consider installing a backup generator connection to keep essential operations running during power outages. Always work with licensed professionals for utility installations and obtain necessary permits before beginning any work.

Creating an efficient industrial laundry room doesn’t have to be overwhelming. By focusing on key design elements like proper space planning, ergonomic workflow patterns, and strategic equipment placement, you can develop a functional space that serves your needs perfectly. Remember to prioritize safety features, including proper ventilation, slip-resistant flooring, and clear pathways between machines.

When implementing your design, start with the basics: establish your budget, measure your space carefully, and plan for future growth. Consider beginning with essential equipment and gradually expanding as needed. Don’t forget to incorporate adequate storage solutions and sorting areas to maintain organization and efficiency.

Keep sustainability in mind by choosing energy-efficient machines and implementing water-saving measures. These investments may cost more initially but will pay off through reduced utility bills and environmental impact. Make sure to include proper lighting, both task and ambient, to create a safe and comfortable working environment.

Regular maintenance schedules and clear operating procedures will help preserve your investment and ensure smooth operations. Consider creating a detailed manual for staff training and reference, including cleaning protocols and equipment maintenance schedules.

Finally, remember that the best industrial laundry room design is one that can adapt to changing needs while maintaining efficiency. Don’t be afraid to make adjustments as you discover what works best for your specific situation. With careful planning and attention to detail, you’ll create a laundry facility that serves your needs for years to come.